The Future of Dental Education Is Digital by Design

Image credit: Kansas City University

Key Takeaways:

- Digital is essential and evolving: Digital dentistry is now a baseline expectation for patient care and dental education, and it will continue to change rapidly.

- Design must enable flexibility: Facilities play a critical role in digital integration. Long‑term projects must anticipate future space needs by aligning curriculum, operations and technology.

- Strategic investment shapes the future: As technology becomes more affordable, intentional investment in flexible digital infrastructure prepares graduates to deliver smarter, faster and more sustainable care.

The future of dental education belongs to those who embrace technology as a catalyst for progress, shaping a generation of clinicians equipped to deliver smarter, faster and more sustainable care in a fully digital world. The physical environment is a significant contributor to the successful integration of digital dentistry, and the design process is a unique opportunity to explore the potential of the latest technology and calibrate its approach to align with its mission. The degree in which an institution invests in digital design is no longer a competitive advantage, it is a necessity to meet the expectations of patients, and to prepare students for a wide range of care delivery settings once they graduate.

As digital dentistry becomes integral to dental education, it brings new considerations for curriculum design and the spaces that support it. Here are three key questions to ask when evaluating these changes.

1) How are intraoral scanners utilized within operatories?

Intraoral scanning, which uses scanners to generate digital 3D models of teeth and oral tissues, has significant implications for how space is planned and used.

Mobile intraoral scanning units offer flexibility and can be more financially accessible. It is prudent if utilizing mobile scanners to consider units from multiple companies, allowing students to experience a variety of platforms as a learning opportunity.

Integrating scanners into the delivery system is a financial commitment to technology, however it can allow for space savings in the overall operatory size, reduce the need for storage of mobile scanning carts, and prepares the institution for the integration of next-generation diagnostic technologies. Research is underway to leverage AI and advanced technologies to integrate diagnostic imaging into intraoral scanners which would eliminate the need for x-rays, resulting in a more streamlined patient experience and reduce radiation exposure.

2) Where do students design dental devices?

Historically, institutions have a dedicated “CAD Design Room” which houses robust computers, requiring students to share access to the resources. Dental schools have many options for protocols as they design a future learning environment:

Scanners integrated into each operatory allow students to design at the patient chair within the clinic. This may be more applicable for advanced degree programs where there is typically one chair per resident. This approach would be challenged in DMD/DDS clinics as most institutions have a chair to student ratio of about 1 chair per 2 DMD/DDS Students.

Issuing students laptops with design software could be an equitable way to ensure all students have access to the required technology and allow students to work in an environment suitable for their learning style. Institutions must consider protocols for patient identification safety.

Instead of a dedicated design studio, faculty can utilize group practice rooms to teach students about dental design, resulting in space savings.

3) Is production off-site, distributed or centralized?

Upon completing a QA/QC process with faculty, students send their devices into production. If an institution is constrained on space or resources they can elect to locate production off-site, which can allow them to use the resources they have to the highest and best use.

With same-day implant appointments gaining in popularity, most institutions choose to have production on-site. On-site production also serves as a learning opportunity; faculty can oversee production. It is typical to have a room dedicated to each step in the 4-step production process to address unique infrastructure needs inherent in milling, 3-D printing, ceramics firing, and trimming and fitting.

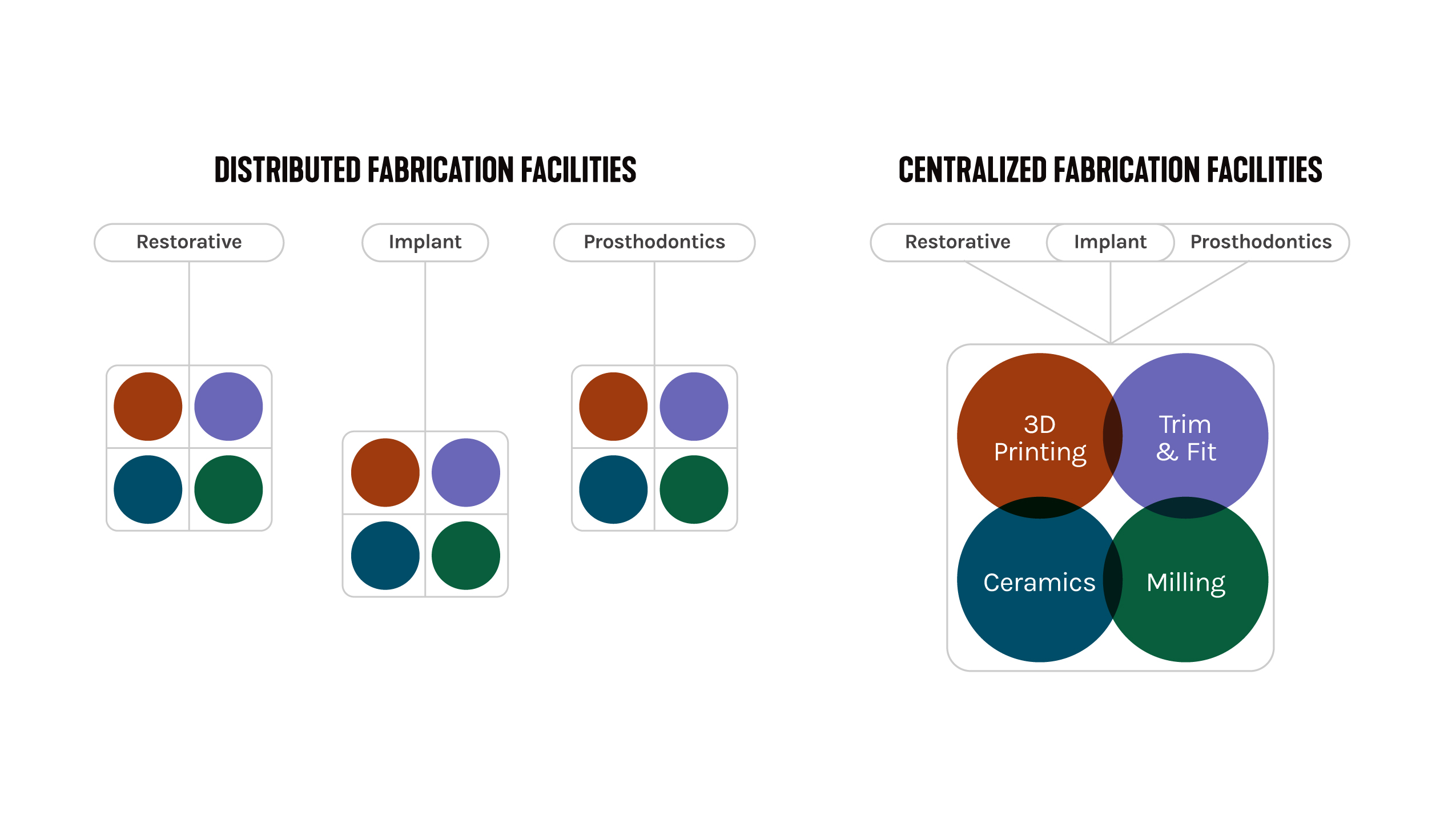

A distributed approach results in each dental specialty such as Implant, Prosthodontics, and Restorative having their own four-room production facility. This is beneficial to the departments because they have full control over their individual spaces and materials. However, this approach results in intense Mechanical, Electrical, and Plumbing (MEP) infrastructure to be distributed throughout a facility. For example, Ceramic rooms and 3-D Printing rooms typically require exhaust hoods above equipment. Due to the high heat generated by ceramic ovens, the two processes are not advised to exist in the same room.

A centralized approach results in combining the production of all dental specialties in one production facility. Centralization offers an efficient use of space, MEP infrastructure and equipment. Institutions can stay at the cutting edge faster, with potentially less equipment to upgrade. Additionally, if three departments each have a 100 square-foot room for 3-D printing, they can combine to one-250 square-foot room, allowing for easier equipment adaptability in the future, less demand on infrastructure loads, and realize net space savings. Larger spaces also allow for easier integration of emerging technologies such as robotics to assist in the production process.

Case Study: Boston University Henry M Goldman School of Dental Medicine (BU GSDM) and SmithGroup

Over 10 years ago, the Boston University Henry M Goldman School of Dental Medicine (BU GSDM) took a bold step forward to be the first US dental school to transition fully to seamlessly integrated Digital Dentistry. Aligning with its strategic plan, this step coincided with the design of a completely transformed facility. Boston University’s innovative approach permeated all aspects of the design. Every operatory has scanning and design capabilities. Support labs used for analog casting were eliminated and replaced with robust production labs to support the digital process. The Simulation Learning Center was designed to introduce students to digital technologies right from the start.

SmithGroup was Boston University’s design partner in shaping their transformative facility. Since then, our team of dental education specialists have worked with over a dozen institutions on renovations, expansions, or new facilities to fit their unique needs. Every institution has their own specific flavor of digital dentistry, with variations depending on their mission, location, class size, existing pedagogy, and faculty interest. Some institutions are aiming to be cutting edge like Boston University, while most others are carefully calibrating resources between analog and digital technologies. Many faculty agree students need exposure to analog fundamentals to both understand the digital counterpart and function in both analog and digital private practice.